The Impact of Automation and the Fabrication/Welding Industry

Automation is increasingly impacting many industries as today’s businesses grow within the digital age. Such industries include fabrication and welding. Many are worried about jobs being replaced by robots. Rapid advancements in artificial intelligence drive fears that truck drivers, customer service representatives, and automotive workers will find their jobs at risk. Will robots take valuable jobs because they can perform repetitive tasks more efficiently than their human counterparts? The answer is more complicated than a simple yes or no. Here are some key ways in which robotics will impact the profession.

The Truth About Robots and Jobs

Hollywood has made big money for years by feeding us images of future societies where robots do all the work. They drive cars, cook food, clean house, and perform all the routine tasks normally done by people. The popular cartoon The Jetsons was created back in the 60s showing a world of flying cars and a robot named Rosie that could produce anything you wanted to eat in the snap of a finger.

There is no doubt that advancements in technology are increasing everyday. Artificial intelligence already allows some cars to drive themselves. Artificial Intelligence now answers our questions and gives us recommendations right in our homes or on the go – like Siri or Alexa, for example. Businesses are using Artificial Intelligence to sift through and analyze mountains of data.

The benefits of these advancements in technology allow businesses to expand their capabilities and grow exponentially without incurring the high overhead costs historically associated with expansion. These nuances help level the playing field and allow smaller companies to compete on a level that was formerly reserved to large businesses with vast resources. Technological advancements create more opportunities for more enterprises, and allow product quality and results to impact the flow of business on greater scale.

All Major Industries are in a State of Change

As industries become more competitive they scramble to increase production and drive down costs. Recent technological advances allow robots to perform tasks that previously required a human worker.

Companies like Telsa are building entire factories with assembly processes that have more robotic components than previously used human workers. These repetitive tasks once performed by a person are now being done by machines.

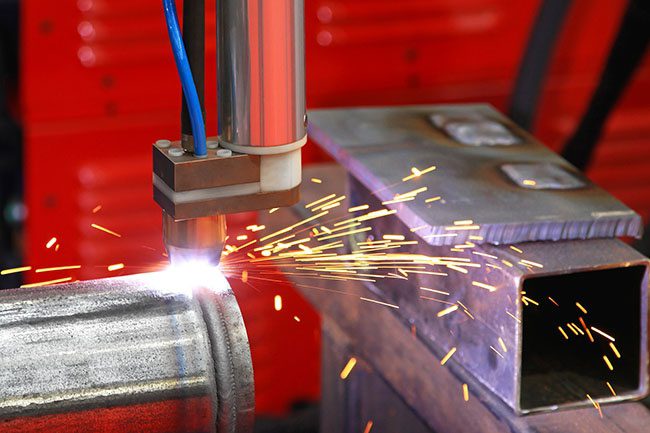

Many areas of the fabrication and welding industry have also found a way to leverage technology in this regard. One example of this is structural steel fabricators using Ficep beam line technology to enhance the speed and accuracy of cutting and drilling steel beams replacing the former process of manually measuring, cutting, and drilling the beams.

This increase in productivity not only allows the various steel beams fabricated for a structural steel project to be produced with precision, but also creates a safer environment for workers as it requires less moving of these large steel beams during the fabrication process. This leads to efficiencies in the erection of the project as the pieces fit together perfectly.

The Welding Industry Continues to Grow

There are still growing personnel needs within the welding industry, which has been growing at approximately six percent per year. This trend is expected to continue.

Welding is an area that requires a skilled workforce, and it continues to experience a shortage in qualified operators. More welders retire each year, and manufacturers struggle to fill the gaps with skilled workers. Leaders in the industry can fill vacant jobs with the most experienced and talented teams, leaving routine work to automation.

Many Tasks Can’t be Automated

It’s important to remember that humans are indispensable. Welding robots may improve efficiency, but not every task can be turned over to a machine with artificial intelligence. Decision making during the the fabrication and welding process often requires real-time adjustments, and factors previously unaccounted for.

Consider these differences:

- Humans have flexibility. Robotic welders are used for specific, repetitive tasks. The robot needs additional programming to adapt to jobs requiring more than one type of weld in one specific situation.

- People show leadership. Robots can only react in pre-programmed ways when things go wrong on the job. People can evaluate the big picture and make decisions to correct the situation, so productivity can resume.

- Humans Are Creative. Robots can’t accomplish tasks that require creativity and inspiration. Custom metal fabrication is an art form. It requires not just skill but originality. Even the most advanced robots don’t possess a creative mind.

- People Can Make Changes. Metal fabrication involves bending and cutting metal to achieve a desired result. Each job, each cut, and each product is different. It takes a human to achieve the best results in custom fabrication.

Swanton Welding uses state-of-the art processes for custom metal fabrication. We use technology to make our products more precise, decrease waste, and make our company safer for the people who work there. We also have experts to provide our customers with beauty and craftsmanship that stands out. Contact us today to find out why Swanton Welding is your best choice for custom welding and fabrication.