Reasons to Go With Custom Fabricated Industrial Toolboxes

Industrial workers commonly rely on employer-provided tools and toolboxes on a jobsite. Employers can choose to invest in budget-friendly toolboxes that break down in a matter of months or invest in a high quality, custom-built toolbox that will serve individual users and the company well for years. A custom fabricated industrial toolbox will often provide more value over time than budget counterparts. Consider some of the most compelling reasons to choose a custom build.

The Problems With Prefabricated Toolboxes

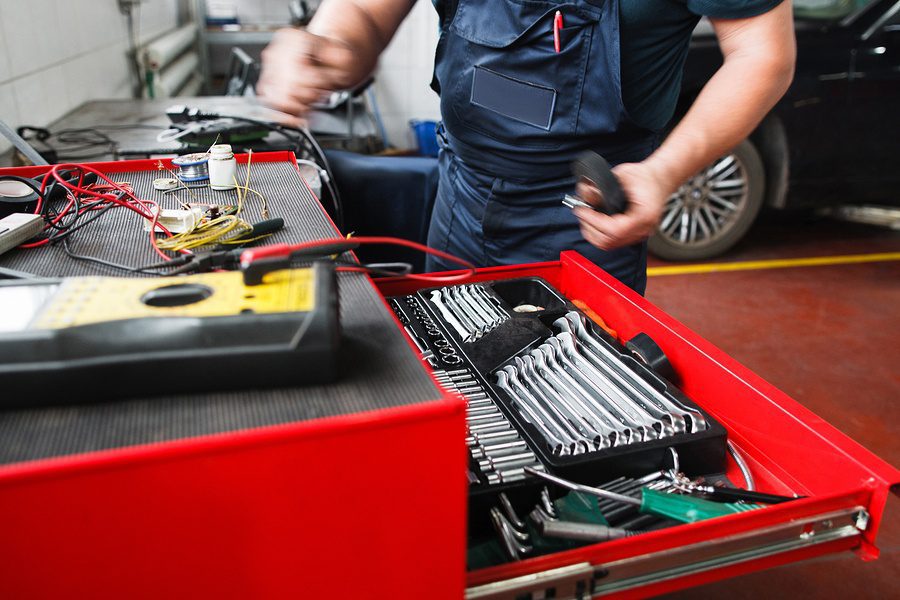

Generic, mass-produced, and standardized toolboxes feature designs to accommodate the most commonly used tools in the industry. The depth, tiered-pullouts, and trays may or may not fit the tools your business uses most often. These basic designs may save the company money right now, but they leave employees searching for places to cram a tool at the end of the day or create tool placement confusion. Productivity, job satisfaction, and project efficiency can falter if employees cannot readily access the tools necessary for the job.

Prefabricated toolboxes fail to live up to expectations in more than one way. They may break down within months of purchase and force the business to pay for toolbox after toolbox. A mass-produced toolbox’s underperforming materials and weight capacity can cause employee frustration. Custom fabrication serves as a viable, valuable, and cost-effective alternative to underperforming prefabricated constructions.

Reasons to Choose a Custom Design

Consider choosing a custom design from the start to enjoy:

- Increased personalization and branding. Many industrial businesses are proud of the equipment they use. Invest in a toolbox that features custom-chosen metals, surface designs, and finishes that both perform well and reflect brand messaging. An employee on the road, at an external jobsite, or parked at work will reflect the brand in a positive light when you invest in a custom-branded and designed toolbox.

- Improved efficiency. A toolbox customized for the job at hand will prevent an employee from rummaging in a bottomless pit. Measurement-specific drawers, tiers, and compartments give employees access to the right tool every time.

- Durability. Plastic and subpar metal constructions will wear out within a matter of months under industrial strain. Custom metal fabricators use hand-selected and durable materials and techniques to give industrial toolboxes the right heavy-duty construction. A properly rated capacity and rust-resistant finishes will keep the toolbox from deteriorating outside or indoors.

- Security. An employee may need to travel to worksites to take measurements, fix industrial assets, or conduct other hands-on activities. A well-made industrial toolbox will protect business tools regardless of location.

- Portability. Some toolboxes remain stationary, while others are designed for portability. A custom fabrication design allows toolbox owners to determine weight limits and portability considerations for maximum efficiency to and from jobsites.

A mass-produced toolbox will get the job done for a short amount of time. Industries interested in long-term value, durability, and efficiency, however, may want to weigh the benefits of custom fabrication over the convenience of prefabrication.

Finding a Custom Fabricator

The right custom fabricator for the job works with heavy-duty, industrial metals on a regular basis. They can meet your specific needs for finishing and design. A great fabricator will even evaluate environmental conditions during the design process. A custom industrial toolbox should perform as well on its first day as it does 15 or 20 years into the future.

At Swanton Welding Company Inc., we handle a variety of custom-toolbox orders from new and long-term clients. Durability, satisfaction guarantees, and quality craftsmanship often trump convenience. Choose Swanton Welding Company Inc. for your next custom toolbox order.