Ways to Drive Down the Cost of Your Fabrication Project

There is no doubt that one of the main components of any fabrication project is the cost. The material, labor, and shipping of these fabricated components to their final destination are all factors in the project investment.

So, what are some ways that we can reduce the cost of a fabrication project without sacrificing the quality of the end product? This is an excellent question.

Here are some ways you can save some money on your next metal fabrication project:

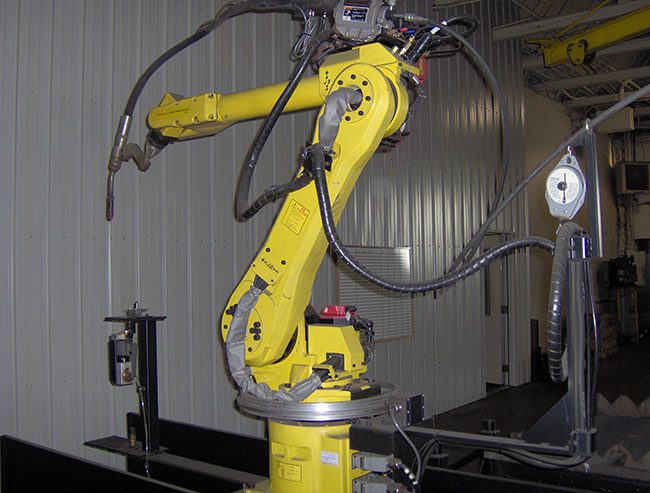

Use Modern Equipment

An experienced and qualified fabrication company will have updated essential equipment available on-site. Ask to tour facilities and see if modern equipment is being used which allows fabricators to improve workflow and product quality. Use of advanced equipment containing the latest in technology will generate a precise end product minimizing costly errors.

Provide the Fabricator With Good Drawings

Precision is important. Complex designs require detailed plans and experienced teams. Any deficiency in the workflow can lead to costly errors and delays during fabrication.

It’s important to provide your fabricator with concrete designs and well thought out project details. Incomplete drawings or drafts of any format require additional development and professional resources that cost time and money.

Have your design prepared by a professional designer or engineer prior to submitting the materials to your fabricator. Your fabricator will be able to provide an accurate quote using final drawings and can even make suggestions for alternatives to materials or processes that will save you money in the end.

Use an Experienced Team

Find steel fabricators that serve a diverse customer base and have proven themselves over time through a variety of projects. Working with a metal fabrication company experienced in custom fabrication, structural steel, rolling, forming, processing, machining, and finishing will allow you to complete most, if not all, of your fabrication needs with one stop rather than working with multiple vendors.

Look into the financial history. Companies who’ve demonstrated financial stability over a period of years will likely excel at managing resources, even in complex situations.

Check the past and current projects to see if they’ve handled projects similar to yours. The quality of past work indicates the experience with which they’ll approach your project.

Plan Ahead

During the planning phase, consider what obstacles might come up. Communicate with your fabricator. Are there multiple inspections that will need to take place? How will the product be used? Communicate materials restrictions at the outset.

Additionally, the fabricator’s investment in resources and technology reflects the ability to flexibly and proactively address needs and adapt to project specific requirements. A fabrication company that can handle onboarding and streamlining the personnel and equipment required to keep pace with modern demands, can serve your project’s needs with the same agility and attention to detail.

Review the project with your fabricator early in the design phase and consistently throughout. You know what you want, and they know how to make it. Clear communication is key during the early stages to ensure that both parties are on the same page. Needs and preferences that aren’t clearly expressed may lead to unnecessary secondary costs.

Swanton Welding Company, Inc. has been serving customers since 1956. We are dedicated to the production of high-quality custom metal fabrication that continually exceeds our customers’ expectations. Contact us for a project quote today.